Some lithium battery manufacturers are building an energy science system based on material science and digital science, which will start a new journey of battery research and development.

Mainland China is becoming the source of a new round of global power battery technology innovation, and companies are leading the industry with diversified, combined and sustainable innovations.

From May 27th to 28th, on the Lithium Battery Technology Day, a number of lithium battery technologies and product innovations were released, including a 360Wh/kg semi-solid battery with a cruising range of 1,000 kilometers, battery swapping technology, and smart mobile energy storage charging pile.

The energy science system based on material science and digital science will open a new journey for the battery technology industry. Strengthening technological innovation, ternary and iron-lithium standard batteries that comprehensively cover battery cells, manufacturing processes, project management, quality, and testing have started mass production.

360Wh/kg semi-solid battery

The further improvement of the energy density of power batteries poses a greater challenge to safety. One of the effective ways is to develop a solid-liquid hybrid semi-solid battery. Around this, power battery companies are making great efforts to tackle key problems. The semi-solid battery developed and marketed can achieve monomer energy density through a series of new materials and technologies such as cathode electrode material particles coated with solid electrolyte, new high-safety functional separator, high-safety liquid electrolyte, silicon anode electrode, and composite current collector. Up to 360Wh/kg, and has passed the most stringent acupuncture test, and can also pass the 180℃ 30min hot box test higher than the national standard, and has been loaded into the car.

Models equipped with semi-solid batteries have a battery pack capacity of 160kWh, a cruising range of up to 1000km, and an acceleration time of only 3.9s per 100 km. In addition to the 360Wh/kg ternary semi-solid battery planned to be mass-produced this year, the 400Wh/kg ternary semi-solid battery has been successfully tested. In the future, it will also be implemented through technological innovation in silicon-based anode iteration, lithium metal anode and pre-lithium technology to accelerate the transition from liquid batteries to semi-solid state, and ultimately to achieve all-solid state.

Bottleneck of LFP battery.

Focus on lithium iron phosphate battery technology, and continuously break its performance limitations through continuous technological innovation.

The laboratory samples of 210Wh/kg cells that have been released in 2021 are mainly used to improve energy density by using cathode electrode material doping modification and structural design, pre-lithiation technology, thick electrode technology, etc. The network can significantly increase the energy density of the battery and reduce the sheet resistivity of the thick electrode, while taking into account high energy density and power characteristics.

On this basis, the lithium iron phosphate monomer energy density 210Wh/kg product is applied to the field of battery replacement to realize the integration of charging, replacement and storage. At present, products based on this technology have received bulk orders.

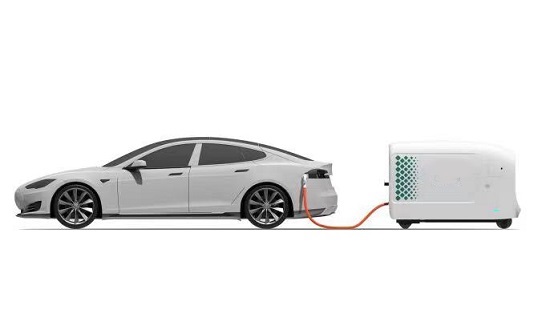

Mobile energy storage charging

Product innovation focuses on mobile energy storage charging.

With the increase in the penetration rate of electrification, the convenience of charging in the application link has become the most concerned “pain point” for consumers.

Consumer-oriented products in the field of mobile energy storage and charging – intelligent mobile lithium battery energy storage charging piles, which have the characteristics of easy layout, multi-scenario, large capacity and high power – is the best solution for the integration of distributed storage and charging in cities.

Mobile energy storage charging, from the perspective of electricity consumption, frees charging from the shackles of the power grid, realizes grid peak shaving and valley filling and reduces grid load, making charging safer and more secure.

From the perspective of the site, charging breaks through the limitation of space, no infrastructure construction is required, and the deployment is more flexible;

From the perspective of application scenarios, it breaks the inherent limitations, that is, the charging pile is also an energy storage station, which can double the economic benefits.

The leading lithium battery companies have established a comprehensive R&D layout covering core materials, cell structure, pack, equipment, safety design, etc., and have created a powerful scientific verification platform, advanced trial production platform, and accurate simulation platform to support the completion of the development and verification from materials, cells, packs to the full life cycle of technical products, it promotes the continuous innovation of battery research and development, as well as innovation.

Facing the TWh era, the technological competition among power battery companies is no longer a single product or technology competition, but a competition of technology and product originality, systematic and continuous innovation and industrial commercialization capabilities. Only battery companies with such capabilities will have the opportunity to remain invincible in a rapidly evolving market.