Lithium-ion battery is a rechargeable battery, in lithium-ion batteries, the selection of foil materials for cathode (negative electrode) and anode (positive electrode) is based on its electrochemical performance and physical characteristics

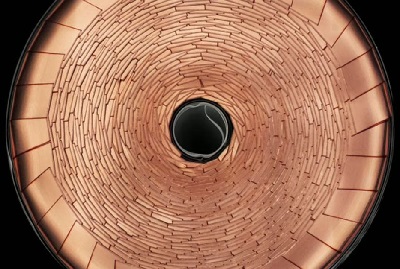

Lithium battery copper foil cathode

Copper: excellent electrical conductivity and chemical stability

The reason why copper foil is used for the cathode/negative electrode piece is that copper has excellent electrical conductivity and chemical stability.

The negative electrode of lithium-ion batteries usually uses graphite material, which is a material with high electrical conductivity.

As a material for the negative electrode piece, copper foil can effectively conduct current and withstand the high current density of the battery. In addition, copper foil also has high mechanical strength, which can maintain the structural stability of the battery electrode

Aluminum: higher specific surface area and lower density

The reason for using aluminum foil for positive electrode pieces is mainly that aluminum has a higher specific surface area and lower density.

The cathode of lithium-ion batteries typically uses lithium transition metal oxides as active materials, such as lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4).

These cathode materials need to react with lithium ions in the electrolyte to release the charge. As the material of the positive electrode piece, aluminum foil has a high specific surface area, which can increase the loading of the active material, thereby improving the energy density of the battery.

In addition, aluminum foil also has good electrical conductivity and chemical stability, and can withstand the high current density of cathode materials.

Summary

In summary, the material selection of lithium-ion battery electrodes is based on its electrical conductivity, chemical stability and mechanical strength.

Copper foil, as a negative electrode sheet material, can effectively conduct current and withstand high current density, while aluminum foil, as a positive electrode sheet material, has a high specific surface area and low density, which can increase the load of the active material.

These options can improve the performance and energy density of lithium-ion batteries.

+8613906047998

+8613906047998