Coating method of ultra-thin solid electrolyte membrane on the surface of NCM811 electrode

Layered nickel-rich oxide is a promising cathode material for lithium-ion batteries with high energy density, but the problem of poor cycle performance due to instability of the electrode-electrolyte interface remains to be resolved.

The surface coating of materials is one of the powerful means to solve this problem, but most of the current researches apply this technology to the material particles instead of the electrode itself, and it is hoped that the coating layer has a larger coverage and protection area.

NCM811 electrode coating

However, recent studies have shown that particle coating may not achieve the desired effect, because the electronic insulation of the coating layer will hinder the electron transmission inside the electrode, so a more precise coating strategy needs to be proposed.

Since the surface is the first barrier of the electrode and is directly exposed to the electrolyte, complex deposits continue to accumulate on it, so it should be the area most in need of protection.

Coating the electrode surface

Magnetron sputtering can be deposited only on the outermost side of the substrate, which is suitable for coating the electrode surface.

Therefore, we use magnetron sputtering technology to prepare an ultra-thin lithium phosphorous oxynitride (LiPON) film on the surface of LiNi0.8Co0.1Mn0.1O2 (NCM811) electrode. Such simple and accurate coating can perform CEI Modified and played a multiplier effect.

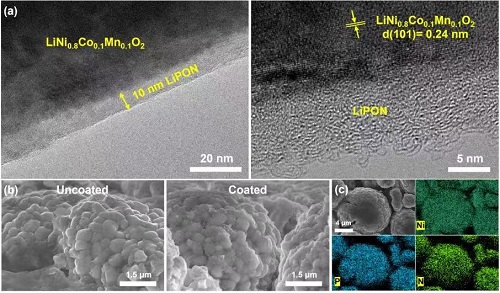

Magnetron sputtering technology was used to prepare 10 nm LiPON on the surface of the NCM811 electrode. TEM and SEM results confirmed the presence of an amorphous coating on the electrode surface

In order to explore the mechanism of the improvement of NCM811 electrode performance by LiPON coating, the K-edge absorption spectrum of P and 2D XRF were first used to test the surface of the two electrodes.

It was found that the surface of the coated electrode had significantly less electrolyte decomposition products such as LixPFy, LixPOyFz, etc., and the P element distribution on the surface of the coated electrode was significantly more uniform than that of the uncoated electrode.

Surface more uniform

This shows that the presence of the coating effectively inhibits the side reactions between the electrode surface and the electrolyte, and makes the CEI composition on the electrode surface more uniform.

In addition, comparing the TEM photographs of the particles on the surface of the two electrodes after the cycle, it is found that the thickness of the CEI on the surface of the uncoated electrode is very uneven, while the CEI on the surface of the coated electrode is integrated with the coating layer and the thickness is uniform.

The XPS surface and depth analysis and characterization of the two electrodes further show that there are obviously more electrolyte decomposition products on the surface of the uncoated electrode, such as Li2CO3, LixPFy, LixPOyFz, etc., while the composition of the coated electrode surface is still LiPON. Mainly, this is also consistent with the above-mentioned XAS and XRF results

Immediately afterwards, the TOF-SIMS test was performed on the positive electrodes of the two batteries after cycling, and it was found that compared with the uncoated positive electrode, the content of Li2PO2+ and HPO42- on the surface of the coated positive electrode was significantly higher, while the content of NiF3- was significantly lower.

The existence of the LiPON coating layer is confirmed and LiPON effectively inhibits the corrosion of the electrode by the hydrolysis product HF of LiPF6. The IC test results of the electrolyte of the two batteries further indicate that the presence of LiPON reduces the HF content in the electrolyte.

The XPS characterization of the negative electrodes of the two batteries further illustrates that the existence of the coating layer makes the phenomenon of the dissolution of the transition metal completely suppressed.

+8613906047998

+8613906047998