Tesla 4680 Battery-Battery Technology Upgrade-Part 2.

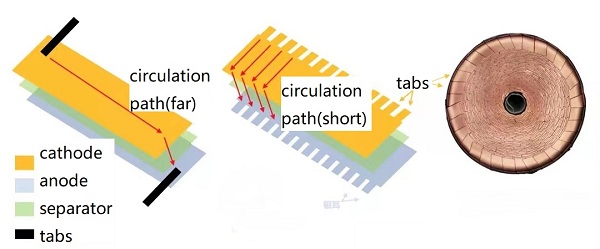

2.1.2. The advantages of all tabs of 4680 battery

1. Improved output power: the battery current path is widened, and the internal resistance is greatly reduced, the internal loss is reduced accordingly, and the battery power is greatly increased (6 times that of the 2170 battery).

2. Improve safety: Cylindrical batteries are different from sheet batteries in that the heat dissipation is mostly axial, and the heat is emitted from the tabs. The traditional cylindrical battery such as 2170 has only two tabs, and the heat transmission channel is narrow, so the heat dissipation effect is not good. The 4680 battery’s tab area is greatly increased, and the heat transmission channel is wide, which greatly improves the heat dissipation effect (only 20% of the traditional cylindrical battery), and enhances the thermal stability of the battery.

3. The fast charging performance is greatly improved: due to the all-pole structure, the electrons are easier to move inside the battery, and the current rate is increased, so the charging and discharging speed is faster.

4. Improve production efficiency: eliminate the process and time of adding tabs to the production line, save equipment space, and reduce the possibility of manufacturing defects.

2.1.3. Difficulties in the process of all tabs

1. The problem of collecting the tabs in the production of all tabs: The popular understanding is the process of folding the tabs together. Currently, there are three types of tabs: rubbing tabs, cutting tabs, and multiple tabs:

All tabs of 4680 cell

1) The shape of the tab of the rubbing tab is not controlled, and short circuit is easy to occur. The two sections are closed during manufacture, and the electrolyte infiltration is hindered;

2) The Tesla is cut obliquely into slices and rolled up, which is better than random extrusion. It occupies less space, but the surface undulation is larger. The two sections are still closed during manufacture, and continuous production cannot be performed with liquid injection;

3) Multi-pole ears are difficult to fold neatly, and the position error of the tabs is easy to be enlarged in the outer ring.

2. In the connection of all poles with the collecting plate or shell, the laser welding technology requirements are high: from spot welding (traditional two poles) to surface welding (4680 battery full poles), the welding process and the amount of welding are all If it increases, the laser intensity and focal length are not easy to control, and it is easy to weld through and burn into the inside of the battery cell or there is no welding. The current battery yield rate is low (80%).

……To be continued

+8613906047998

+8613906047998