Continued: 4680 Battery-Battery Technology Upgrade-Single crystal anode

5.2. Single crystal anode

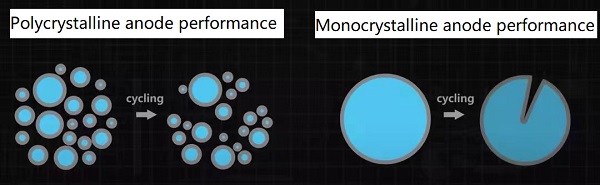

Different from increasing the nickel element to increase the energy density, single crystallization is to increase the energy density by increasing the voltage of the cathode material: single crystal materials are more suitable for high voltage than traditional polycrystalline materials, and there is no grain boundary, which can improve the ternary battery The thermal stability and cycle performance.

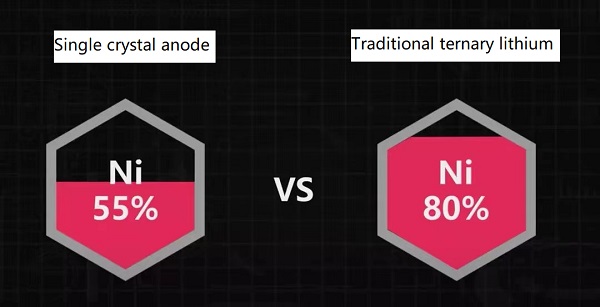

Nickel content of single crystal anode

Monocrystal anode improves battery cycle performance

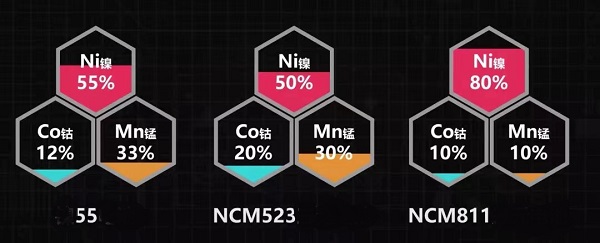

Taking the 5-series as the representative high-voltage single crystal material nickel 55 battery, only using the same nickel content as NCM523, the energy density of NCM811 can be achieved, and the thermal stability of the material is more prominent, and the cost is lower than that of NCM811.

Composition comparison of nickel 55 and NCM battery

5.3. 4680 battery positive trend

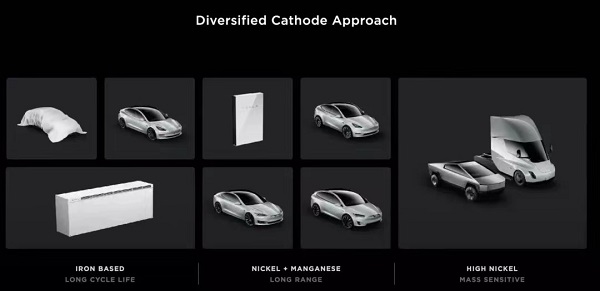

The 4680 battery actually has three different cathode materials: iron-lithium, nickel-manganese-aluminum, and high-nickel content.

Three 4680 batteries (iron-lithium, nickel-manganese-aluminum, high-nickel) application

5.3.1. 4680 batteries dominated by high nickel

The 4680 high-nickel version is Tesla’s current main direction. It will be used in the high-endurance Cyber truck and Semi in the future. At the same time, the long-endurance and high-performance versions of Model 3 and Model Y can also be used.

5.3.2. Nickel-manganese will follow high-nickel

After the 4680 high-nickel version has matured, the 4680 nickel-manganese version will be developed, which will be used in products such as Model Y with medium battery life and household batteries.

5.3.3. Lithium iron cathodes in the future

4680 batteries may also use iron-lithium anodes: The Tesla battery press conference did not mention its cycle performance, because the volume expansion of the silicon-based anode reduces the number of charging and discharging.

After the nickel-manganese version of the 4680 battery technology matures, the iron-lithium version of the 4680 battery It can also be launched with a high probability, and it is used in low-priced vehicles and energy storage batteries, focusing on high cycle performance.

The gradual development of battery models from the high-nickel version to the nickel-manganese version and finally to the iron-lithium version of the 4680 battery will drive the demand for related materials.

6. Industrialization progress

- Tesla is the first to release in 2020, and plans to reach 100GWh of 4680 battery capacity by the end of 2022, and 3TWh by 2030.

- According to reports, YW has a leading position in large cylindrical batteries. In 2021, 4680 and 4695 finished products have been produced, and they have been recognized by downstream car companies. The planned 20GWh large cylindrical battery capacity for passenger cars is expected to start mass production in 2023.

- Panasonic plans to start trial production of 4680 batteries in Japan in March 2022. The technical goal of 4680 battery product development has been basically achieved, but there are still technical thresholds for large-scale mass production.

- LG, Samsung, CATL, BAK, Honeycomb and other battery companies are also under development. The application of large cylindrical batteries will further promote the development of high nickel materials.

7. Conclusion

The core innovation process of the 4680 battery is: large cell + full tab + dry cell technology, which enhances battery power and safety, improves production efficiency, fast charging performance, and reduces battery costs.

There is room for further improvement in energy density and cycle performance. . The current technical difficulty lies in the production and welding of the full tab, and the dry electrode process.

The 4680 battery is the first to be applied to the high nickel system. Tesla and Panasonic are expected to start mass production in the first half of 22, which will drive the demand for high nickel cathode + silicon carbon anode + carbon nanotube conductive agent + large cylindrical structure + new lithium salt. The leader will benefit;