GF Lithium’s first-generation solid-state battery vehicle is about to be delivered

On December 10th, the first batch of E70 electric vehicles equipped with hybrid solid-liquid lithium-ion batteries was tested. It is expected that the model will be delivered before the Spring Festival

Solid electrolyte membranes

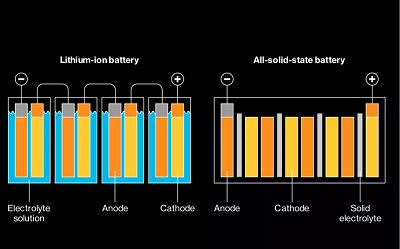

It is reported that the battery electrolyte adopts the oxide route, and the anode electrode adopts graphite. There are separators, but unlike traditional separators, solid electrolyte membranes are used.

Solid State Batteries & Liquid Lithium Ion Batteries

For this hybrid solid-liquid lithium-ion battery, the relevant person in charge stated that the technology has realized the loading of hybrid solid-liquid lithium-ion batteries with flexible solid-state separators.

Performance & safety

This battery not only has excellent electrochemical performance, but also can be achieved by needle punching, extrusion, overcharge, high temperature hot box, etc. Abuse tests that are higher than the most stringent national standards.

The battery pack efficiency is high. The module adopts aluminum alloy frame and high-precision seam laser welding technology to reduce redundant structure design and increase the overall grouping rate to more than 86%, which is ahead of the average level of the soft pack module industry.

Full-solid-state battery 2.0

At the same time, the second-generation full-solid-state battery is being developed, with an energy density exceeding 360Wh/kg.

It is understood that the current vehicles on sale are equipped with traditional liquid lithium batteries. Some market views believe that solid-state batteries are unlikely to be used in low class cars at this stage, and that this model may be an unlisted concept model.

However, as one of the development directions of next-generation power batteries, the development of solid-state batteries has attracted the attention of the industry, and many companies also have technical reserves.

Since 2017, GF Lithium has combined its own advantages in the battery industry chain and has invested heavily in the deployment of solid-state batteries in advance.

Judging from the previously disclosed content, GF Lithium’s first-generation hybrid solid-liquid electrolyte battery products have passed a number of third-party safety tests and a number of customer sample tests, with an energy density of 235-280Wh/kg.

In April of this year, GF Lithium added an annual output of 7,000 tons of metal lithium and lithium materials, and will build a high-specific energy solid-state battery ultra-thin lithium anode material factory in phases.

At the same time, the company is continuing to expand its 1GWh solid-state battery production capacity to support the development of new energy businesses.

It is understood that a 0.3GWh mixed solid-liquid lithium-ion battery production line has been built and has mass production capacity. At present, the production line has been officially put into use.

In the future, as solid-state batteries gradually mature, the electrolyte and separator markets will undergo changes.

Status quo

However, solid-state batteries can only be used in a small number of high-end electric vehicles before 2030, which is difficult to have a major impact on the existing liquid lithium battery industry, and has a weak impact on the separator sector.

At present, Chinese domestic and foreign battery companies that have laid out solid-state battery technology routes include CATL, and car companies such as Toyota, Volkswagen, etc.