Under the wave of electrification demand, the industry predicts that the global lithium battery market will maintain a medium-to-high growth trend in the next few years.

By 2025, reach 1523GWh

During the large-scale production and manufacturing of lithium batteries, more and more battery companies are paying attention to energy consumption. Among them, workshop dehumidification, as a process with high energy consumption, has an increasingly prominent impact on the quality and cost of lithium battery production.

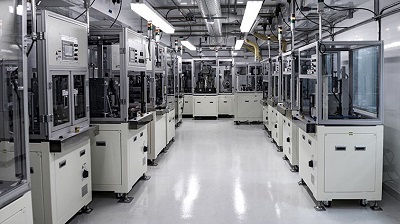

Lithium battery manufacturing equipment

JR Air is currently at the forefront of the industry in the field of dehumidification. In the field of lithium batteries, it has developed environmental protection equipment and harmful gas recovery devices. Customers have covered domestic CATL, ATL, BYD, GX High-tech, FN Technology, YW Lithium Energy, Honeycomb Energy, Gateway Power; overseas Sweden Northvolt, American Tesla, etc.

According to reports, the 60°C low-temperature regeneration, 80°C medium-temperature regeneration, and high-temperature air inlet energy-saving rotary dehumidification units developed in recent years have stable performance and significant energy-saving effects. They have passed Tesla, CATL, YW Lithium Energy, and Honeycomb Energy. Wait for the verification of the customer’s long-term use.

Through the improvement of the dehumidification process and the optimization of the treatment process, the standard double-wheel low dew point dehumidifier is now upgraded to a super-efficiency single-wheel low dew point dehumidifier. When the new product is within 10% of the effective fresh air, the outlet air dew point is less than -50°C, the regeneration energy consumption of the 10,000 air volume unit is reduced by 30%, and the overall unit cost is reduced by 20% to meet the requirements of the low dew point lithium battery workshop of most return air units.

By increasing the energy efficiency ratio and reducing the regenerative power, while at the same time reducing the cost under the premise of the same stability, thereby improving the cost performance, to meet the requirements of customers to reduce costs and strengthen market competitiveness.

In order to meet the needs, strategy is:

First, through technological innovation, continue to introduce new products to speed up the technical upgrade of the dehumidification and drying system in the lithium battery industry;

Second, the production scale continues to expand, with a monthly output of 100 units On this basis, continue to increase production capacity to ensure the provision of high-quality, efficient and cost-effective products.