Why do electric vehicles need 800V charging ? The rise of silicon carbide is a “perfect match” with the 800V high-voltage platform system of electric vehicles.

Different from the charging requirements of the energy storage lithium battery system, the power battery charging technology of pure electric vehicles is purely in some controversial discussions.

Under the hot trend of 800V high-voltage platforms, according to industry forecasts, SiC power components will enter a stage of rapid development with the large-scale deployment of 800V platforms in the next few years.

Silicon carbide and 800V can be described as “mutual achievements”, and they both have “bright futures”.

![]()

Why 800V?

Whether it is a manufacturer or a car owner, the effect of “charging for 5 minutes and lasting 200km” is a dream. In order to achieve this effect, it is necessary to solve two difficulties:

- First, it is to greatly improve the charging performance and quickly increase the charging speed of lithium batteries.

- Second, it is to improve the operating efficiency of the vehicle and extend the driving mileage under the same amount of electricity. We can simply understand it with primary physics: P=UI. So if you want to increase the power, there are two ways: to increase the current or increase the voltage.

The high current will lead to high heat loss of the charging gun, cable and core components of the power battery, and the theoretical upper limit is not large. Therefore, the road of increasing the current “cannot go through”, no, it should be “cannot go too far”.

So, what about raising the voltage?

When the system current remains unchanged, the charging power will double with the system voltage, that is, the peak charging speed will double, and the charging time will be greatly shortened.

In addition, under the same charging power, when the voltage is higher, the current can be reduced, and the wire is not so thick, and the resistance thermal energy consumption of the wire is also reduced.

Therefore, the charging power can be increased if the same charging wire size used for the original 400V is also used. This means that under the 800V platform, thinner charging wires can be used.

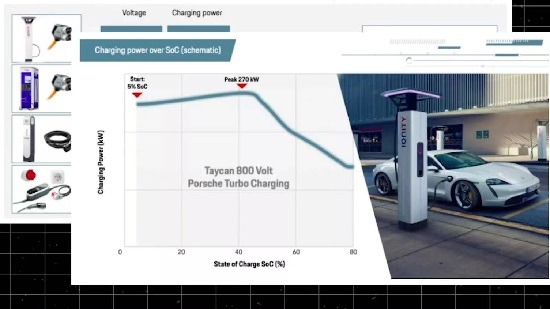

Studies have shown that fast charging using 800V high-voltage mode supports 30%-80% SOC maximum power charging, while low-voltage high-current mode can only perform maximum power charging at 10%-20% SOC, and the charging power drops very rapidly in other range . It can be seen that the 800V high-voltage mode can support faster charging for a longer time.

The higher operating efficiency of the vehicle means that when the current remains unchanged, the higher the battery voltage, the greater the power of the motor, and the higher the efficiency of the motor drive.

Therefore, the 800V high-voltage platform is easy to achieve high power and high torque, as well as better acceleration performance. Although it is said that the improvement of energy supplementation efficiency brought by 800V to electric vehicles is qualitative, one of the biggest obstacles to the promotion of 800V is cost.

What will the 800V platform bring?

Why is the cost issue? If the electric vehicle structure is upgraded to 800V, then the standard of its high-voltage components will be raised accordingly, and the inverter will also be replaced from traditional IGBT devices to SiC material MOSFET devices.

The inverter itself is a component whose cost is second only to the battery. If it is upgraded to SiC, the cost will be raised by another level.

However, for OEMs, when applying silicon carbide, the cost of power devices is generally not considered alone, and more importantly, the cost of the entire vehicle is considered.

Therefore, it is very important to find the balance between “cost savings brought by SiC” and “its own high cost”.

When it comes to SiC, the first to try is Tesla.

In 2018, Tesla replaced the IGBT module with a silicon carbide module for the first time in the Model 3. At the same power level, the package size of silicon carbide modules is significantly smaller than that of silicon modules, and switching losses are reduced by 75%. Moreover, after conversion, using SiC modules to replace IGBT modules, the system efficiency can be improved by about 5%

In terms of cost structure, the replacement cost has risen by nearly USD 225,00. However, due to the improvement of the efficiency of the whole vehicle, the installed capacity of the power battery has decreased, and the cost of the battery has been saved.

This is a big gamble by Tesla, which has flattened the cost due to its huge market sales. Tesla also took the lead in occupying the technology and market of 400V battery systems with this gamble.

In terms of 800V, Porsche, as the first car company to try, installed the 800V system in the all-electric Taycan sports car launched in 2019, setting off a wave of 800V high voltage arms race for electric vehicles.

Analyzing the cost from Porsche is quite “inappropriate”. After all, it focuses on luxury cars and pays attention to a brand premium.

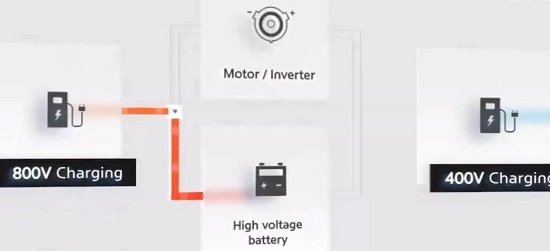

However, in the development and application of technology, this is a big project that “affects the whole body”. For example, under 800V high-voltage charging, the voltage of the lithium battery pack should also be relatively raised to 800V, otherwise it will be burned due to high charging current.

In addition, it involves not only the charging system, but also the battery system, electric drive system, high-voltage accessories and wiring harness system, which affect the starting, driving, and the use of air conditioners of the vehicle.

The original Taycan did not come up with a voltage platform composed entirely of 800V electrical appliances. Porsche could not find an air-conditioning compressor with an 800V working voltage, but combined two high-voltage systems of 400V and 800V through a DCDC converter, and Some compromises and concessions have been made in the fast charging speed of the battery.

Which first ? Chicken or egg ?

At a practical level, for OEMs, launching a product with a high-voltage platform without supporting infrastructure will still make users face the problem of charging difficulties. The problem of “the chicken or the egg” has also evolved into the problem of “the car waits for the pile” or “the pile waits for the car”.

Under the premise of 800V, the existing charging piles should be upgraded. Compared with the previous ordinary charging piles, the cost of 800V high-power charging piles has at least doubled, or even reached 2 to 3 times. For economical models, the distribution of 800V high-power charging piles on-board will greatly weaken their price competitiveness.

Secondly, the extremely high charging power is a huge challenge to the power grid. Whether it can be promoted on a large scale also depends on the infrastructure capacity of the power grid.

However, for charging pile operators, high-power fast charging can also help improve profitability. When car companies scramble to deploy 800V technical route, the number of high-voltage and high-power charging piles adapted to it will also increase in parallel.

In addition, some car companies have also launched the laying of their charging piles, which is the so-called self-operated overcharge.

For example, Tesla’s supercharger network and some OEMs have proposed plans to build their own 480kW high-voltage superchargers, and innovatively combine 800V fast charging and energy storage systems.

In order to turn 800V products from concept into reality, practical problems in infrastructure such as high-power charging piles and power grid infrastructure capabilities need to be solved.

Core shortage

In addition, the “core shortage” will also have a certain impact.

The application scale guarantee of 800V models requires a stable supply of SiC. The application of silicon carbide needs to consider technology upgrades and market effects, and will not complete the replacement of silicon-based IGBTs in a short time.

However, with the arrival of 800V, not only inverters, but also on-board chargers, DC/DC converters and charging piles have strong demand for SiC. According to the latest forecast, the SiC device market will grow from a $1 billion business in 2021 to more than $6 billion by 2027.

The 800V electrical route upgrade has a long-term trend, and SiC benefits the most. Other components are smoothly upgraded, and the SiC device is expected to come. Finally, with the implementation of the energy-replenishing infrastructure, 800V high voltage is the ultimate complete body, and can truly reach the “800V era”.

+8613906047998

+8613906047998