Besides lithium battery energy storage, hydrogen is also a new energy source with great potential !

Hydrogen is mainly present in water and fossil fuels in the form of compounds on the earth, and hydrogen energy, as a secondary energy source, needs to be “extracted” through hydrogen production technology.

Grey, blue & green hydrogen

At present, the main source of hydrogen is the production of hydrogen from fossil fuels. The hydrogen produced in this way is called “grey hydrogen” or “blue hydrogen” (depending on the purity).

And green hydrogen, specifically refers to hydrogen produced by using renewable energy (such as solar energy, wind energy, nuclear energy, etc.), it has no carbon emission in the whole production cycle, and it is of great significance to reduce greenhouse gas emissions!

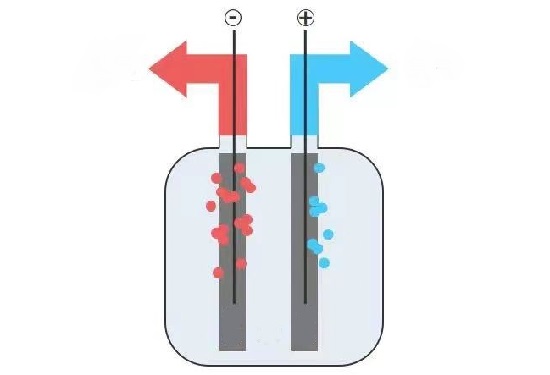

One of the important ways to produce green hydrogen is to electrolyze water to produce hydrogen. Electrolysis is a well-known chemical process: water produces hydrogen and oxygen in an electrolyzer.

Since the “conducting” ability of pure water is extremely poor, a suitable proportion of electrolyte will be added to the water to help improve the electrolysis efficiency.

For example: alkaline water electrolysis hydrogen production is the process of water electrolysis hydrogen production carried out in an alkaline electrolyte environment.

Under the action of direct current, the electrons of the positive electrode will move to the negative electrode, and the water and electrons near the negative electrode will undergo a hydrogen evolution reduction reaction to generate hydrogen and hydroxide ions; the hydroxide ions will pass through the diaphragm and move to the vicinity of the positive electrode and lose electrons, resulting in Oxygen evolution oxidation reaction which produces water and oxygen.

Electrolysis equipment

In addition to electrolyzer, what equipment is needed for hydrogen production?

As the core component of the reaction, the electrolyzer is often the most concerned equipment, which is related to the gas production, energy consumption, and service life of the entire system.

But in fact, after the hydrogen is produced from the electrolyzer, it still needs to go through multiple processes.

The most basic hydrogen production system includes two major accessories: electrolyzer + post-treatment system.

Compared with gray hydrogen and blue hydrogen, green hydrogen contains almost no impurities and can reach 99.8% without purification.

In addition, there is a power supply system, which can convert AC into DC power through an inverter. If it is off-grid power generation, it also needs to go through the process of DC to DC, and the specific situation is analyzed in detail.

There is also a water supply system. The general urban tap water must contain certain impurities, which need to be treated and used, and the water quality varies from place to place. The impurities will affect the service life of the electrolyzer.

Finally, there is an intelligent control system for real-time monitoring of the operating status of the system, continuous purity detection function

With the diversified development of the new energy industry, in the future, green hydrogen production equipment and solar energy, wind energy, and lithium battery energy storage systems will form an automatic adjustment system for power generation and energy storage. Green hydrogen has actually become a new energy storage solution.