The principle of lithium battery production and manufacturing process is not complicated, but the main process control points of lithium battery manufacturing technology are not so simple。

Cathode electrode ingredients: The cathode electrode is composed of active material, conductive agent and binder.

First, drying: confirm and bake

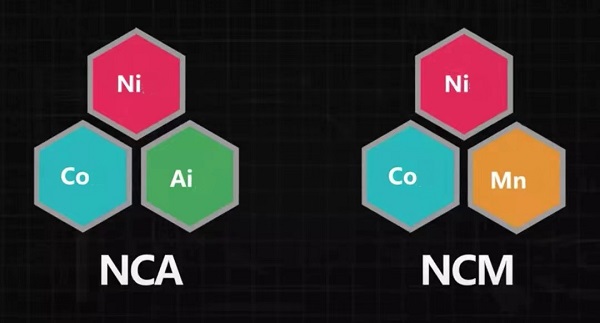

Generally, the conductive agent needs to be baked at ≈120 °C for 8 hours, and the binder PVDF needs to be baked at ≈80 °C for 8 hours. For active substances (LFP, NCM, etc.), it depends on the state and process of the incoming materials. It depends on whether baking and drying are required. At this stage, the workshop requires temperature: ≤40℃, humidity: ≤25%RH.

PVDF glue (PVDF, NMP) preparing

The quality of PVDF glue is crucial to the internal resistance and electrical properties of the battery. The factors that affect the glue are temperature and stirring speed, the higher the temperature, the yellowing of the glue will affect the adhesion. If the stirring speed is too high, it is easy to break the glue, the specific rotation speed depends on the size of the dispersing plate.

Generally, the linear speed of the dispersing plate is 10-15m/s (high dependence on equipment), and stirring is required at this time. The tank needs to open the circulating water, the temperature: ≤30℃.

Cathode electrode slurry matching

At this time, it is necessary to pay attention to the order of feeding: first add the active substance and the conductive agent to mix slowly, then add the glue, the feeding time, and the feeding ratio, which must be strictly implemented according to the process.

Secondly, it is necessary to strictly control the revolution and rotation speed of the equipment (generally, the dispersion line speed should be above 17m/s, depending on the performance of the equipment, which varies greatly from manufacturer to manufacturer), and the vacuum degree and temperature of the stirring.

At this stage, it is necessary to regularly check the particle size and viscosity of the slurry, and the particle size and viscosity are closely related to the solid content, material properties, feeding sequence and process technology.

At this time, the conventional process requires temperature: ≤ 30 ℃, humidity: ≤ 25%RH, Vacuum degree≤-0.085mpa

Transferring

After the slurry is prepared, the slurry should be transferred out to the transfer tank or coating workshop.

When the slurry is transferred out, it needs to be sieved. The purpose is to filter large particles, precipitate and remove ferromagnetism and other substances.

Large particles affect the coating to the end, which may lead to the risk of excessive self-discharge or short circuit of the battery, too high ferromagnetic material in the slurry will lead to excessive self-discharge of the battery and other defects.

The process requirements at this time are temperature: ≤ 40 ℃, humidity: ≤ 25% RH, screen mesh ≤ 100 mesh, particle size ≤ 15um (parameters are for reference only).