As of now, global leading battery companies plan to produce more than 3.5TWh of lithium batteries by 2025.

Under the tide of large-scale expansion of lithium battery production, as an important part of lithium batteries, the demand for electrolyte has increased significantly, and the price has also risen.

Outlook to 2025

The agency predicts that by 2025, the global demand for lithium battery electrolyte will reach 2.163 million tons, and in 2030 it will reach 5.485 million tons, of which more than 85% of the demand will be met by Chinese companies.

The electrolyte is composed of electrolyte lithium salt and high-purity organic solvent, which is the carrier of lithium-ion migration and charge transfer.

Electrolyte is a key material that affects the performance of lithium batteries such as high voltage and high specific energy. In recent years, as the demand for lithium batteries in new energy vehicles, energy storage and other application markets continues to grow, the output of electrolytes is also increasing.

Technical Upgrade

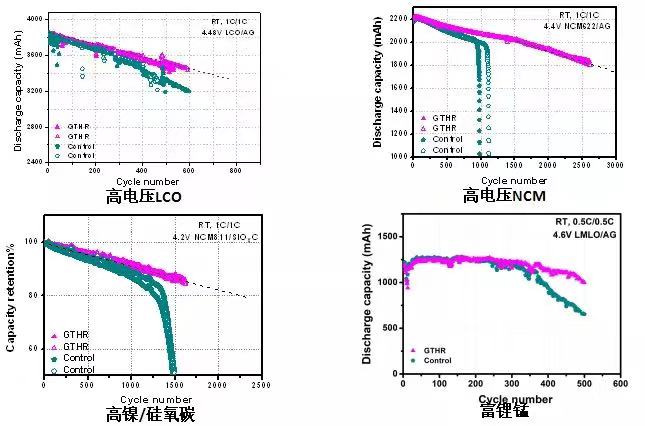

But at the same time, with the continuous development and iteration of new technologies and processes for lithium batteries, the market continues to strengthen the requirements for high nickel, high voltage, high specific energy, high safety and other characteristics, and the applicability of the electrolyte requires corresponding technical upgrades

For example, high-nickel cathode materials have become the current mainstream technology route for high-energy-density lithium batteries. With the continuous increase in the proportion of nickel and the tentative use of silicon-carbon anodes, new challenges have been brought to the development and production of electrolytes.

At the same time, in order to alleviate “mileage anxiety”, the energy density of lithium batteries continues to increase, and the voltage will also increase accordingly. The higher the voltage, the greater the challenge to the performance of the electrolyte, which may adversely affect the performance and safety of lithium batteries.

In addition, the storage performance, cycle performance and safety performance of lithium batteries in high temperature, fast charging and other environments are closely related to the performance of the electrolyte.

The above-mentioned industry difficulties are more complicated to solve, and the technical threshold is high. Facing the development trend of new technologies, leading electrolyte companies have been working on electrolyte technology to meet the new requirements of new material systems for electrolytes.