The price of raw materials such as lithium carbonate continues to fall, and the price of energy storage equipment may usher in an inflection point.

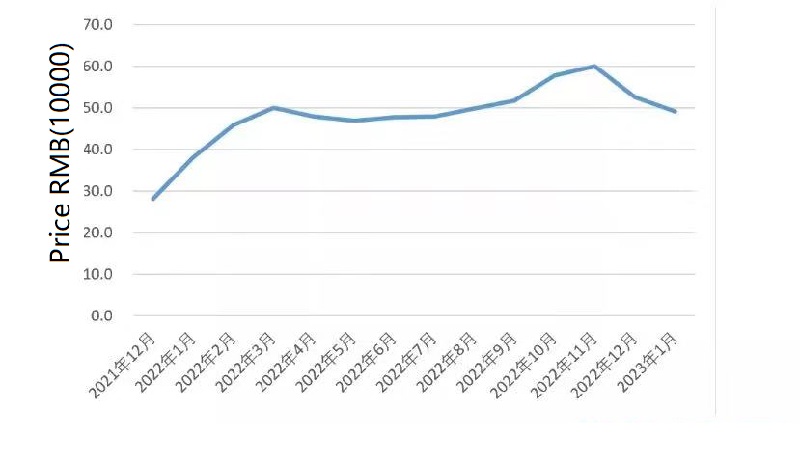

Recently, the prices of major raw materials such as lithium carbonate have continued to decline. Taking the price of battery grade lithium carbonate, the cathode raw material of lithium iron phosphate battery, for example, as of January 9, the price of battery grade lithium carbonate was about 492000 yuan/ton, which has fallen below 500000 yuan/ton.

Price of Lithium Carbonate

Falling Prices

The composition of lithium iron phosphate battery mainly includes cathode material, anode material, diaphragm, electrolyte, copper foil, aluminum foil, etc.

The cathode material accounts for about 40-45% of the total cost of lithium iron phosphate battery, and occupies the core position in lithium iron phosphate battery.

Lithium carbonate is the most important raw material for lithium iron phosphate battery and accounts for the highest proportion of the total cost. At present, the price is close to the price level at the end of March 2022, but the price increase is still relatively large compared with the price at the beginning of 2022.

In the past two years, with the booming and sustained rapid growth of the electric vehicle and energy storage market, manufacturers have expanded their production capacity with the help of future prospects and the capital market, leading to structural overcapacity of some materials.

As the price of lithium carbonate, the cathode raw material with the strongest price of raw materials, continues to decrease, the price of the main raw materials of lithium iron phosphate batteries has been fully loosened. For example, the price of graphite, lithium hexafluorophosphate electrolyte, copper foil, PVDF and other materials has dropped significantly, especially lithium hexafluorophosphate, PVDF and other materials have dropped by more than 50%.

The energy storage battery accounts for about 60% of the equipment cost of the energy storage system and about 50% of the overall investment of the energy storage power station.

It is estimated that the cost of electrochemical energy storage system will be reduced by more than 30% by 2025. The decrease in the price of raw materials is crucial to promote the reduction in the cost of energy storage systems.

Trend

At the stage of rising prices of various raw materials and increasing battery costs, battery manufacturers initially absorbed the rising space of battery costs by sacrificing profits. When the cost increase exceeded the enterprise’s affordability and the imbalance between supply and demand, battery prices gradually increased. Therefore, battery prices have a lag in the rising stage.

Large-capacity and long-life batteries are the trend of energy storage battery development. Energy storage battery manufacturers have adopted 280Ah and above large-capacity batteries or 560Ah large-capacity batteries to effectively reduce the cost of energy storage system. At the same time, the life cycle cost of the energy storage battery can also be reduced by extending the number of battery cycles and delaying the decay of the battery.

At present, there is still a certain gap between the cost per kilowatt hour of lithium iron phosphate battery energy storage and that of pumped hydropowerenergy storage. At the same time, the technical and economic efficiency of other types of energy storage is also gradually improving.

How to reduce the initial investment cost and life-cycle cost of lithium iron phosphate battery energy storage and improve its economic efficiency is an important factor determining its future development prospects