Striving to break through technological processes, improve battery cell yield, and scale delivery capabilities has become the common goal of companies in the lithium battery large cylindrical cell industry chain.

The large cylindrical battery industry has ushered in the “dawn moment” of the concentrated release of diversified market demands.

46 series large cylindrical lithium batteries

Tesla announced that the production capacity of 4680 battery cells has reached 17GWh; Yunshan Power has put into production a 1.5GWh large cylindrical battery mass production demonstration line.

BMW announced that its new generation of large cylindrical batteries will soon be installed in new models with the sixth-generation eDrive electric drive system, and it is expected that the Chinese factory will start mass production of the first new generation model in 2026.

Yiwei Lithium Energy announced that it has been designated as a supplier of large cylindrical batteries for FAW Bestune.

The 4680 large cylindrical battery cell project has been successively increased in production and put into mass production, further clarifying the signal of large cylindrical batteries being used in vehicles.

Battery & upstream industry chain

Since this year, companies including CATL and EVE Energy have also successively promoted production capacity progress and continued technological iteration of 4680 series lithium battery cells.

The application potential of large cylindrical batteries goes far beyond EV. Whether it is industrial and commercial energy storage, light vehicles, humanoid robots, eVTOL or AI data center BBU, etc., there is considerable incremental space for the market application of large cylindrical batteries.

LG, SDI, and SK on have also deployed 46 series large cylindrical batteries, confirming the application potential of large cylindrical batteries in new scenarios.

Diverse scenarios, expanding boundaries

Large cylindrical batteries have become an ideal choice for many emerging scenarios due to the comprehensive advantages in energy density, rate performance, group efficiency, standardization, high safety and long life as well as cost.

In the low-altitude economy, eVTOL has put forward performance requirements for batteries that exceed those of traditional power batteries. Some battery manufacturers have proposed specific goals to achieve mass production of 400Wh/kg-level lithium battery products and small-scale mass production of 500Wh/kg-level products by 2025.

Humanoid robots

In addition to the combination of “semi-solid + large cylinder” being applied to the eVTOL market, humanoid robots will also provide application scenarios for the expansion of large cylindrical batteries.

Humanoid robots require lithium batteries to meet multiple requirements such as high energy density, high power, high rate, high safety and long life at the same time, which is undoubtedly where large cylindrical batteries come in handy. By 2030, the global demand for lithium batteries for humanoid robots will reach 50-80GWh.

Application in AI

NVIDIA plans to include BBU (Battery Backup Unit) as standard in the new generation of server GB3800, which will not only reconstruct the technical direction of emergency power supply system in data center, but also open up new application space for large cylindrical batteries.

BBUs using lithium battery technology are more competitive:

- First, the 5-10 year service life and fast charging characteristics can significantly reduce the full life cycle cost

- Second, in the high-voltage DC power distribution system used in the new AI data center, the high-rate BBU can show higher power conversion efficiency, which helps to optimize the data center operating cost structure.

The power increase of AI servers is driving the rapid iteration of BBU technology, plus data center BBU attaches great importance to safety and stability and is insensitive to battery cell costs. The large cylinder with full-tabs can significantly improve the thermal safety of battery cells, so it will also become a high-value-added application market.

Tesla’s 4680

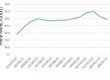

Tesla first launched the industrialization process of 4680 large cylindrical batteries in 2020. The first generation of 4680 battery cells were mass-produced in 2021, the second generation of welded 4680 battery cells in 2022, and the dual-electrode dry-process 4680 batteries in 2024. Many problems were encountered during the iteration process, resulting in delayed delivery.

The technical process of China’s 46 series large cylindrical battery cells is completely different from that of Tesla’s 4680. For example, Tesla’s 4680 battery uses dry process technology, both the cathode and anode are made by dry processing, and the tab processing by cutting and folding, which greatly affects its mass production progress.

Manufacturing equipment

More technical breakthroughs have been made in the key core processes and equipment technologies of cylindrical full-tabs, and a series of cylindrical full-tab intelligent equipment covering different structures and process technologies, multiple equipment forms, and tiered mass production needs (50PPM-360PPM) are now available, achieving mature application and batch delivery of cylindrical full-tab battery mass production assembly lines.

Through multiple new welding systems such as laser modulation technology, better spatter suppression and more refined welding processes can be achieved, effectively improving product consistency and reducing production costs, helping to fully realize refined and large-scale manufacturing of large cylindrical batteries.